The integrated WRB/AB gypsum sheathing of DensElement® Barrier System combines efficiency with high performance to help achieve faster dry-in and mitigate installation risks. Able to be used behind many of today’s top cladding choices, DensElement® Barrier System provides a water-resistive barrier and air barrier (WRB/AB) that can be installed in all weather conditions for faster job completion. 1

1 DensDefy™ Liquid Barrier may be applied in temperatures as low as 25°F and cures in temperatures as low as 32°F.

DensElement® Barrier System and DensDefy™ Products help ensure the continuity of your structure’s WRB/AB regardless of design complexity and, with the addition of NEW DensDefy™ Liquid Barrier, maintains continuity across multiple substrates.

DensElement® Barrier System, when properly sealed with DensDefy® Liquid Flashing, eliminates the need for a separate WRB/AB and puts a stop to compromising on your building envelope design during the construction process.

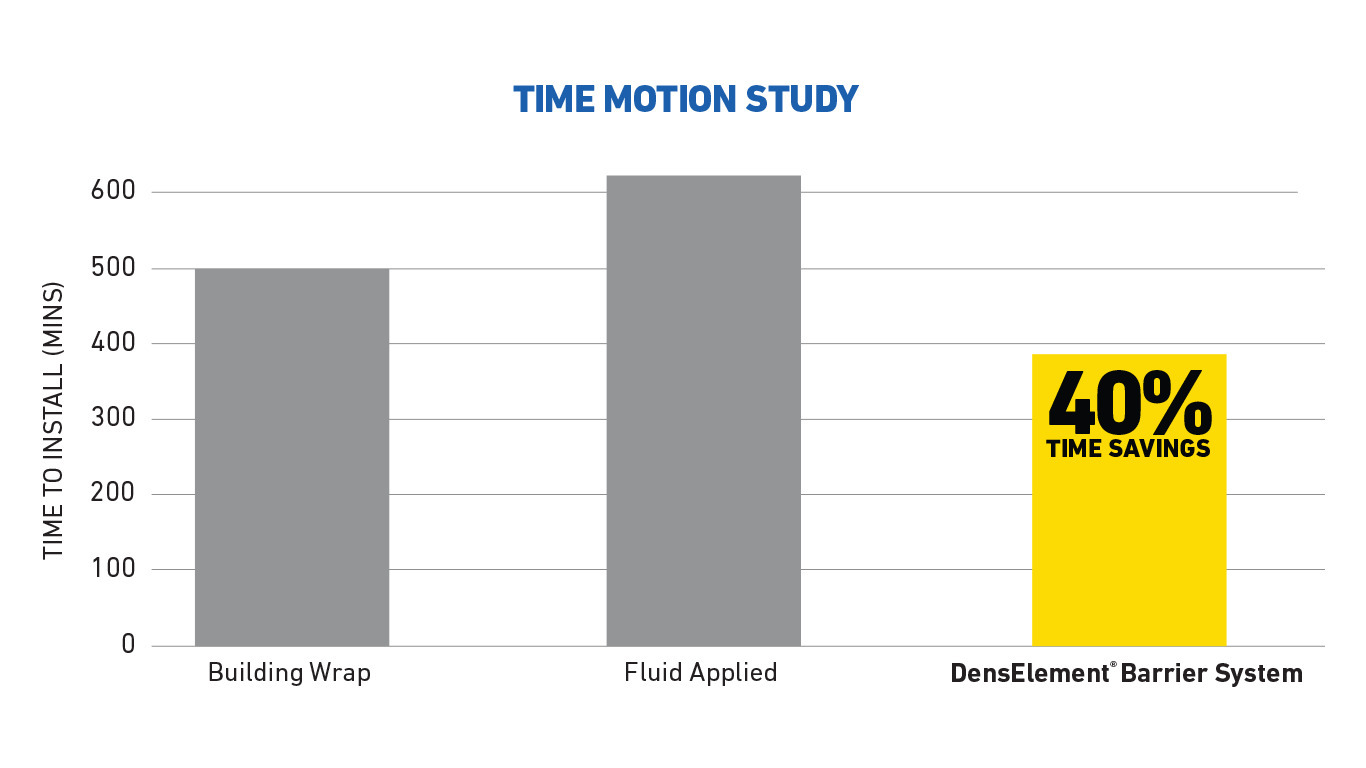

By eliminating the need for a separate WRB/AB, DensElement® Barrier System helps to achieve dry-in in fewer steps, meaning your project gets completed faster.2

Because DensElement® Barrier System can be installed in challenging weather, schedules are accelerated, achieving dry-in faster while improving your structure’s resistance to normal moisture conditions and uncontrolled air movement.

2 To achieve dry-in, all window openings and roof have to be installed.

DensElement® Barrier System frees you from manually applying a WRB/AB over sheathing on your jobsite or in the factory. Resisting normal weather conditions and preventing uncontrolled air movement, it eliminates an entire step in the installation process and helps keep you on schedule.

Compatible with DensElement® Barrier System to ensure continuity of WRB/AB. DensDefy® Liquid Barrier, DensDefy® Liquid Flashing, and DensDefy® Transition Membrane products work together to help protect against water intrusion and mitigate the risk of unwanted air movement.

More than 30 years ago, DensGlass® Sheathing disrupted commercial building design. Now DensElement® Barrier System continues that legacy of innovation by integrating three products in one: gypsum sheathing, water-resistive barrier and air barrier.

- DensElement® Barrier System combines product ideation and experimentation.

- Integrating the fiberglass mat and gypsum core to form a monolithic, hydrophobic surface transforms the entire gypsum sheathing into a WRB-AB that blocks bulk water while allowing vapor to pass through.

All-around DensElement® benefits include faster install, dry-in, less crew needed and less jobsite waste.

- Eliminates separate WRB-AB application step.

- Installs in wet weather.

- May be exposed to normal weather conditions for up to 12 months.

Our Testing Matrix demonstrates a sampling of the specific experiments performed on the system to replicate potential real-world exposure. This exhaustive testing resulted in the evidence needed for the International Code Council to confirm the performance of the DensElement® Barrier System as a combination exterior wall sheathing, water-resistive and air barrier (WRB-AB) system (ESR-3786).

DensElement® Sheathing is manufactured to meet ASTM C 1177. Application standards for DensElement® Sheathing, where applicable, are in accordance with Gypsum Association publication GA 253 for gypsum sheathing and ASTM C 1280.

Introducing Georgia-Pacific Building Products’ DensDefy™ Liquid Barrier

How to Apply Georgia-Pacific DensDefy™ Liquid Flashing

How to Apply Georgia-Pacific DensDefy™ Liquid Flashing to Rough Openings

DensElement® Barrier System brings even more efficiency to off-site construction by reducing time-consuming steps that slow down production.

The collaborative Design-Build approach maximizes production speed and minimizes risks from design to constructability, aligning all involved project team members from the start.

Tapping into offsite construction opportunities throughout your project can increase efficiency to help save resources, time and money. Offsite construction helps your team move through the process early in your development cycle, so you can take full advantage of the benefits it has to offer.

3The results presented reflect the findings on specific construction assemblies, under test conditions. Actual results may vary depending on the system, the building, the installation methods, and other factors.